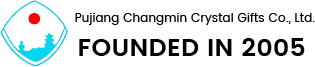

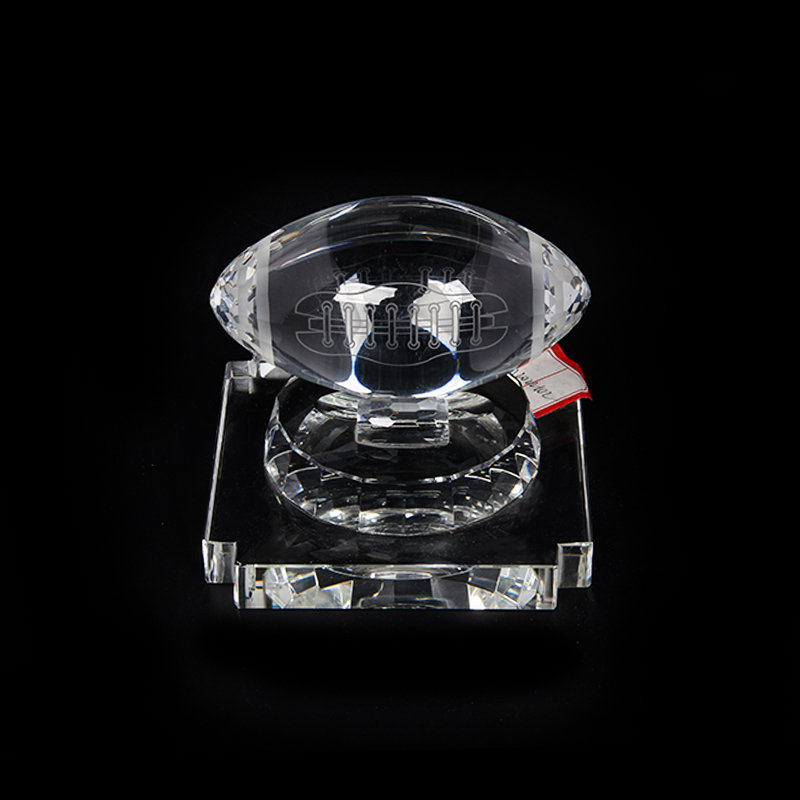

In the world of commemorative awards and corporate gifts, customization has become a defining factor in product selection. One product that continues to attract attention is the Crystal Glass Medal. Known for its transparent brilliance and solid craftsmanship, the Crystal Glass Medal offers a refined aesthetic that suits a wide range of occasions, from sports competitions to academic achievements and corporate recognitions. A major advancement in its production is the integration of Crystal Cube Laser technology, which is transforming how these medals are designed and personalized.

Laser engraving has long been used in various materials, but its application in crystal products has reached new heights with the development of Crystal Cube Laser methods. This advanced technique allows for intricate, three-dimensional images to be embedded inside the crystal without damaging the exterior surface. As a result, the Crystal Glass Medal can now showcase detailed logos, names, dates, and even lifelike portraits suspended within the crystal itself. This innovation adds a unique layer of depth and character that cannot be achieved through traditional surface engraving.

For event organizers and award designers, this technology opens up a wealth of creative possibilities. Each Crystal Glass Medal can be made to reflect the specific theme or message of an event. Whether it's a commemorative symbol, a brand identity, or a personal achievement, Crystal Cube Laser engraving captures it with stunning precision. The clarity of the crystal combined with the internal imagery creates a sophisticated visual effect that makes each medal feel distinct and meaningful.

One of the major advantages of using Crystal Cube Laser engraving is the ability to customize on a small or large scale without compromising detail. This is especially valuable for institutions that require large batches of awards, such as schools, corporations, or sports associations. Each Crystal Glass Medal can carry unique identifiers, such as individual names or award categories—ensuring recipients receive something that feels truly personal. This level of customization can be achieved efficiently thanks to the high-speed precision of the Crystal Cube Laser process.

Moreover, the durability of the engravings makes them long-lasting. Since the laser creates the design inside the crystal, the surface remains smooth and untouched, preserving the clarity and shine of the Crystal Glass Medal over time. This is particularly appealing for customers who want their awards to maintain their elegance years after being presented. The embedded design is also resistant to fading, scratching, or wear, adding to the overall value of the product.

From a production standpoint, the Crystal Cube Laser method is also environmentally considerate. Unlike traditional etching or surface treatments that often require chemicals or abrasives, this process is clean and non-invasive. This makes it an attractive option for manufacturers looking to reduce their environmental footprint while still delivering a high-quality product.

As the market for personalized awards continues to evolve, the Crystal Glass Medal remains a popular choice due to its timeless appearance and adaptability. The incorporation of Crystal Cube Laser technology enhances its relevance by aligning it with current trends in precision personalization. Whether used for sports tournaments, employee milestones, or academic ceremonies, this combination of material and method brings added value to both givers and recipients.

In conclusion, the synergy between the Crystal Glass Medal and Crystal Cube Laser engraving has redefined what is possible in award customization. Through the use of precise internal laser technology, designers can now create detailed, durable, and highly personal awards that reflect the spirit of achievement. As more industries and institutions recognize the benefits of these innovations, it’s clear that this pairing will continue to shape the future of commemorative design.

English

English 中文简体

中文简体 عربى

عربى