In recent years, crystal cube laser engraving and crystal glass medals have become popular choices for individuals and institutions who want to record memories in an exquisite and lasting form. Whether used to mark milestones, honor achievements, or celebrate personal moments, these elegant crystal creations are a thoughtful way to transform important moments into treasures that will be cherished for years to come.

Their unique clarity, combined with the exquisite engraving process, makes them a preferred alternative to traditional awards and souvenirs. Understanding their production process, customization options, and practical applications can help buyers determine which method is more likely to achieve their goals.

Transform Images into 3D Memories

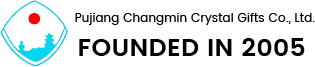

A major feature of crystal cube laser gifts is the ability to embed detailed images into the interior of the crystal. This method relies on a specialized laser to etch the pattern into multiple layers, creating a sense of depth that cannot be replicated by standard surface printing. Instead of fading or peeling over time, these internal engravings remain intact, preserving the integrity of photos, symbols, and text. For example, a wedding portrait transformed into a silhouette floating in a crystal cube can become a meaningful anniversary keepsake. Businesses often use the same technique to embed logos, slogans or anniversaries to highlight their brand image. Since these designs are clearly visible from angles, they can become an eye-catching focal point in display cabinets, offices or home environments.

Crystal Glass Medals for Recognition

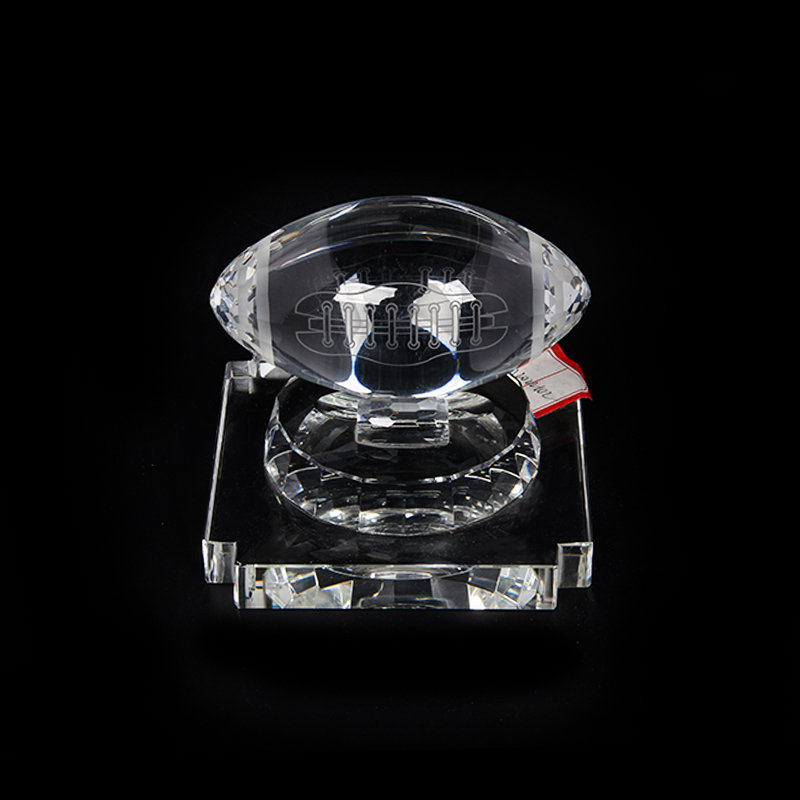

While crystal cubes often serve as decorative mementos, crystal glass medals are valued for their versatility in award ceremonies and recognition events. Their solid structure allows them to be adapted into various shapes, including classic round or custom-cut forms, depending on the theme of the occasion.

Glass medals can be engraved with names, achievements, or meaningful dates, using laser or sandblasting techniques that deliver crisp detail. Whether presented to honor sports achievements, academic success, or corporate milestones, these medals combine a sense of formality with visual appeal. Many organizations also choose to pair them with ribbons or presentation boxes, which enhance their ceremonial value.

Design and Aesthetic Considerations

The impact of a crystal gift often depends on more than the engraving alone. Factors such as the crystal’s transparency, weight, and finish play a role in how the final piece is perceived. High-purity optical crystal ensures light flows evenly through the design, while precise polishing produces a reflective surface that catches attention.

When customizing a crystal cube laser piece or a glass medal, it’s worth considering the balance between imagery and text. Overly complex layouts can make details harder to see, especially from a distance. Clean, centered compositions usually help the engraving appear more vivid. Packaging is another factor that affects presentation. Velvet-lined boxes or satin pouches not only protect the product but also elevate the unboxing experience for recipients.

Beyond Decorative Uses

Though often seen as ornamental, these crystal items have functional applications across different sectors. Companies sometimes use them as promotional gifts or employee awards, while educational institutions present them to graduates or competition winners. Their neutral style allows them to fit seamlessly into diverse contexts, whether formal or informal.

Another advantage is their practicality in logistics. Crystal glass medals and laser cubes are relatively compact and robust, making them straightforward to transport and store in bulk for large events. This practicality contributes to their growing use in conferences, trade shows, and commemorative campaigns.

Production Techniques and Quality Control

Producing high-quality crystal keepsakes requires a combination of advanced machinery and skilled workmanship. Manufacturers typically start by selecting optical-grade crystal for its clarity and strength. During engraving, the laser equipment must be calibrated carefully to achieve consistent depth and alignment. Any deviation can distort the final design or weaken the structure.

Quality control includes thorough inspections for scratches, chips, or internal bubbles. Many suppliers provide digital proofs or prototype samples, giving clients a chance to approve the layout before full production. This process helps maintain confidence in the finished product and reduces the risk of miscommunication.

Flexible Customization and Market Adaptation

One reason these products have remained relevant is their adaptability. From single-piece gifts to large-scale orders, crystal cube lasers and glass medals can be produced efficiently to meet different requirements. Manufacturers often support customer-supplied artwork or photography, ensuring the result reflects the intended sentiment accurately.

Additional features, such as LED bases or custom-shaped stands, can further highlight the engraving and create a more dramatic display. Some designs also include space for QR codes or authentication marks, enhancing both security and storytelling.

As more buyers look for gifts and awards that balance emotional significance with refined presentation, these crystal items continue to fill an important niche. Their blend of precision craftsmanship, clear aesthetic, and customization possibilities allows memories to be captured in a form that feels both substantial and timeless. Whether recognizing a professional milestone or celebrating a personal achievement, crystal glass medals and laser-engraved cubes offer a distinctive way to mark life’s meaningful moments.

English

English 中文简体

中文简体 عربى

عربى