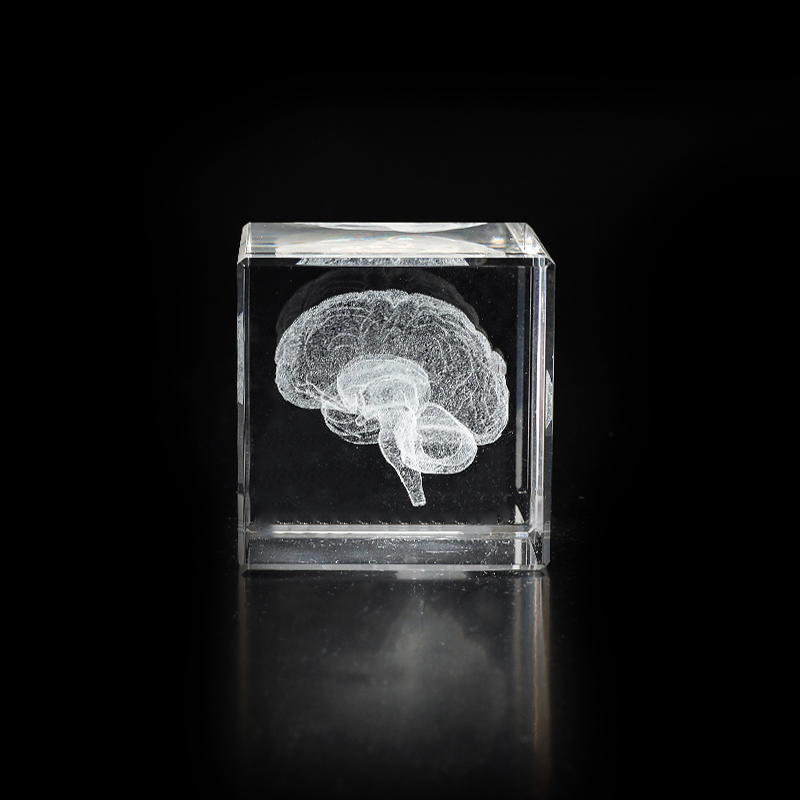

Crystal glass products have become an increasingly popular choice for businesses seeking refined and memorable award solutions. Whether used for corporate recognition, academic achievements, sports events, or commemorative purposes, Crystal Glass Medals offer a unique balance of clarity, weight, and design potential. When paired with precision techniques like Crystal Cube Laser engraving, the final result can reflect the personality of a brand while meeting functional needs such as durability, legibility, and customization.

The Value of Crystal in Recognition Products

Compared to traditional metal or plastic awards, crystal offers a distinct visual appeal. Its transparency and weight create a sense of importance and craftsmanship that enhances the perceived value of the award. For companies and organizations looking to reinforce their branding, a crystal glass medal can function as both a recognition tool and a lasting symbol of identity.

The materials used in crystal medals are selected for optical clarity and surface uniformity. These features not only improve the appearance but also make the medal more suitable for engraving or color-filling techniques. With the growing demand for event-specific and brand-focused awards, the need for adaptable and scalable production processes has never been greater.

Laser Technology for Detailed Branding

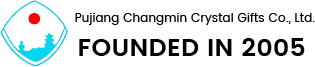

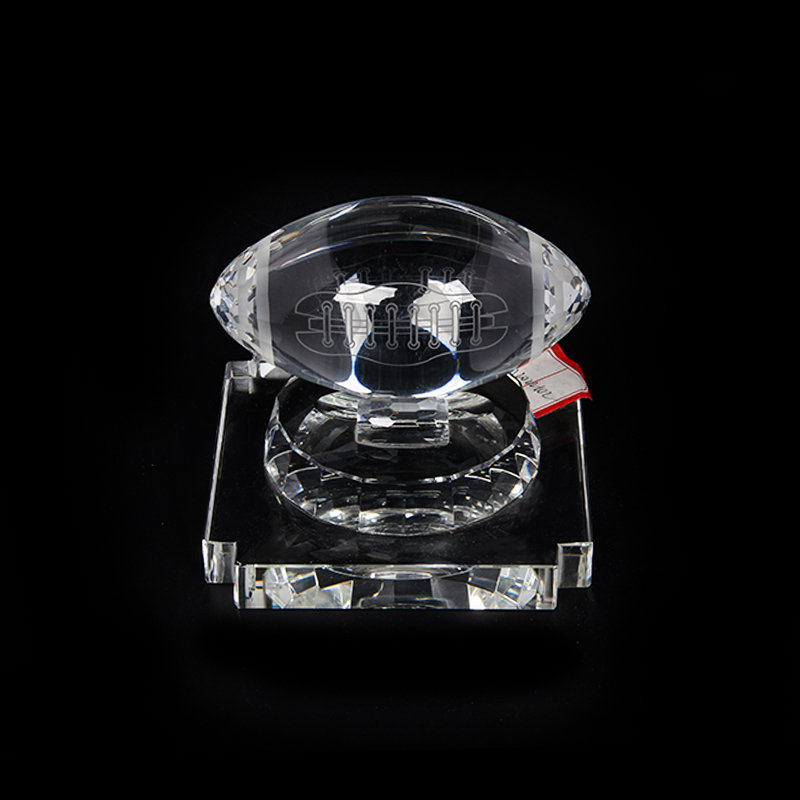

Crystal Cube Laser engraving is a non-contact process that allows precise, internal 3D or 2D etching inside a glass or crystal body. This technology is especially useful for rendering complex logos, emblems, or personalized messages without affecting the external surface of the product. Unlike surface printing, which may fade over time, laser engraving remains intact for the lifespan of the object.

By using computer-aided design systems, manufacturers can import precise brand assets and reproduce them in crystal with relatively little distortion. This precision is essential for brand guidelines that require exact shapes, fonts, and proportions.

Because laser engraving does not rely on surface coatings, the process is also compatible with both small and large batch production. This makes it easier to accommodate projects with varied order sizes, from limited-run commemoratives to bulk corporate awards.

Customization options to meet diverse needs

Every event or brand has different requirements in terms of size, shape and presentation. Crystal glass medals can be customized to a variety of specifications. Some businesses may choose a classic round or oval shape, while others choose a unique geometric profile to create a modern feel. Surface treatments such as frosted edges or beveled profiles can further enhance the design without adding complexity.

Color embellishments can also be added using screen printing or UV-curable inks. Combined with crystal cube laser engraving, these elements can provide a multi-layered visual effect, highlighting depth and craftsmanship. Ribbon fixing points, medal holders or display stands can be adjusted according to how the medal is used or displayed.

Custom orders usually start with a consultation stage, during which technical drawings or design templates are exchanged. When customers clarify usage scenarios, time expectations and packaging preferences at the beginning of the process, they can help ensure smooth production.

Packaging and presentation are crucial

The presentation method is crucial to the overall impression of the award or gift. Crystal medals are often paired with velvet-lined boxes, transparent display cases or custom cartons to reinforce the brand image and protect the product during transportation. Standard packaging options may work, but many customers will opt for branded inserts or personalized covers to create a unified unboxing experience.

For export orders, packaging also needs to consider shipping durability and regional preferences. Working with an experienced manufacturer can simplify these aspects, especially when planning large shipments or coordinating shipments to multiple destinations.

Practical considerations for long-term use

In addition to their visual properties, crystal glass medals are favored for their long shelf life and resistance to wear. If stored and handled properly, they will not tarnish or discolor, making them ideal for long-term display in offices, schools, or exhibition venues. For customers who manage multiple events each year, choosing consistent sizes and formats for all medals can improve inventory planning and support a unified brand story.

It is also worth noting that crystal materials require special care during production and quality inspection. Manufacturers that use advanced equipment such as precision edge grinding machines and in-house laser systems are better able to produce high-clarity products without inclusions or deformations. This helps maintain production consistency and reduces the risk of product rework or rejection.

Crystal awards combine structural stability and visual appeal, and are both practical and ceremonial across a wide range of industries.

Flexible Options for Global Buyers

As crystal awards grow in popularity across Europe, North America, and parts of Asia, customization and export capabilities have become key considerations for buyers. Choosing crystal cube laser engraving as part of the design process helps companies meet regional design standards while streamlining the personalization process.

Suppliers familiar with international shipping and labeling requirements can ensure smooth customs clearance and meet tight deadlines. Whether fulfilling repeat orders or developing new product lines, clear communication of delivery times, packaging details, and usage goals ensures that the final product meets brand and functional expectations.

English

English 中文简体

中文简体 عربى

عربى