In contemporary recognition programs and commemorative gift strategies, crystal cube laser engraving has become a technique that unites visual refinement with a high degree of personalization. Organizations, event planners, and individuals increasingly explore ways to design distinctive pieces that reflect milestones, values, or collective achievements. A deeper understanding of the customization process—particularly when combining crystal cube lasers and crystal glass medals—enables purchasers to make more informed decisions and anticipate the nuances of production.

Assessing the Right Crystal Cube for Your Objective

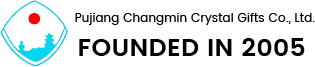

Any effective customization begins with selecting an appropriate crystal cube. Options range from compact cubes designed for modest engravings to substantial pieces capable of displaying intricate logos and multiple lines of text. For corporate award programs or milestone commemorations, larger cubes tend to provide sufficient internal volume for three-dimensional representations and layered designs.

Evaluating optical clarity is essential before proceeding. High-grade glass with minimal inclusions ensures that laser-engraved details remain crisp and uninterrupted by distortions. Subtle imperfections—such as trapped air bubbles—can disrupt the visibility of the final engraving. Verifying glass specifications and requesting production samples help reduce the risk of surprises later in the process.

Preparing Artwork and Adjusting Layout

A central aspect of laser customization involves translating digital designs into engravable artwork. Vector files or high-resolution images form the basis for engraving paths. For designs that include corporate emblems or text, ensuring the artwork is scaled proportionally to the cube’s dimensions helps avoid loss of detail.

When more complex three-dimensional engravings are desired, specialists often convert models into point clouds or layered depth maps. This process enables the laser to define surfaces and contours within the glass with greater precision. Early collaboration with technicians or designers can identify areas where adjustments are necessary, preventing incomplete or distorted engravings.

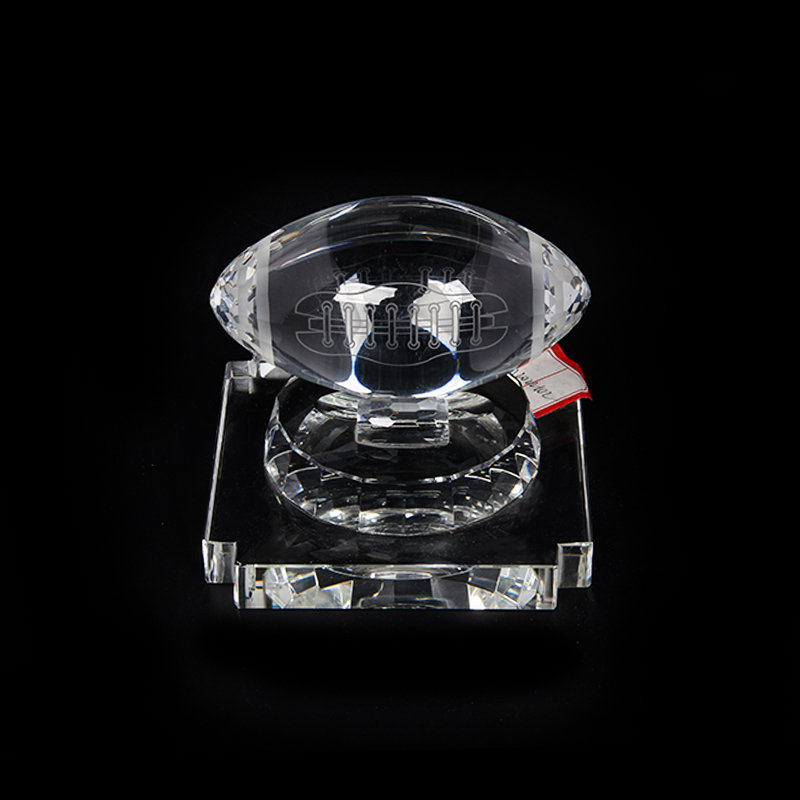

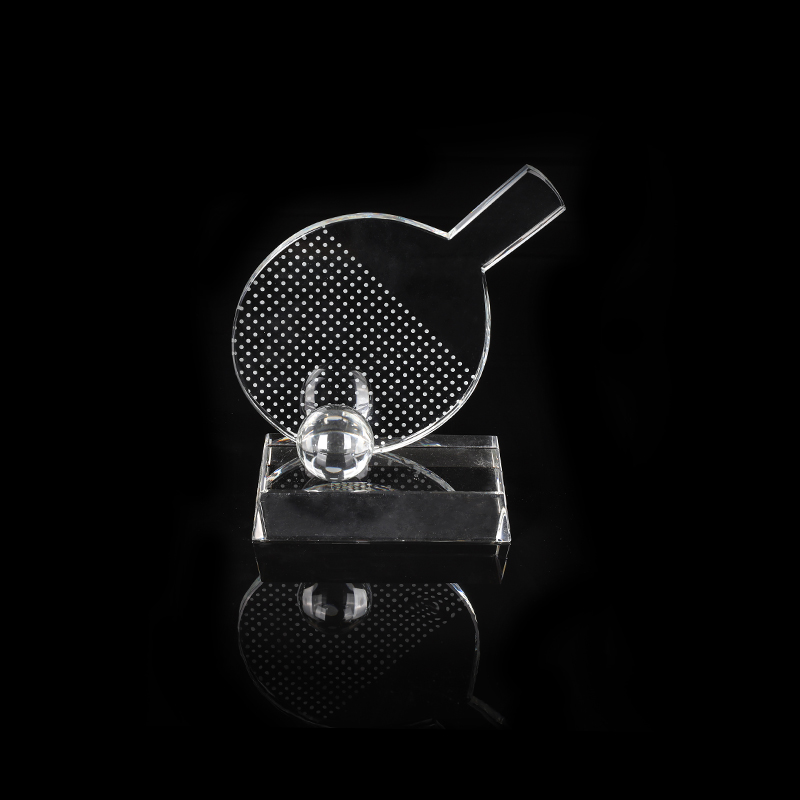

Incorporating Crystal Glass Medals for Cohesive Presentations

Crystal glass medals frequently complement laser-engraved cubes during recognition ceremonies. These medals can carry matching logos, inscriptions, or decorative motifs, creating continuity across multiple award items. Coordinating the finishes—such as polished surfaces or frosted effects—establishes a visual theme that reinforces the significance of the event.

Practical considerations also come into play when ordering both product types. Aligning sizes and shapes ensures the pieces display cohesively, whether presented together in a single package or displayed separately. For organizations focused on traceability, adding engraved batch numbers or serial identifiers can improve record-keeping and support authenticity verification.

Laser Engraving Technologies and Production Insights

Unlike surface etching methods, subsurface laser engraving preserves the smooth exterior of the crystal while forming precise internal imagery. This technology relies on directing concentrated laser pulses into the glass, generating microfractures that create visible points in three dimensions. The process requires careful calibration to maintain focus and spacing consistency across the entire design.

Complex engravings—particularly those involving detailed portraits or multi-layered scenes—can demand longer production cycles and additional proofing stages. Communicating timelines and confirming artwork approval early in the project helps keep delivery schedules predictable.

Quality Assurance and Handling Protocols

Thorough inspection follows every engraving cycle. Each crystal cube undergoes assessment under multiple lighting conditions to confirm clarity and accurate placement. Even slight deviations in orientation can affect legibility, especially for layered or panoramic designs.

Crystal glass medals are similarly reviewed for uniform edge finishing, engraving depth, and surface condition. To maintain standards, some facilities implement automated visual inspection equipment, while others rely on experienced staff to identify irregularities before packaging.

Presentation and Care Recommendations

Presentation strongly influences how recipients perceive customized crystal gifts. Many suppliers offer tailored boxes lined with protective materials to shield the pieces from damage in transit. Incorporating branded inserts, certificates of authenticity, or printed messages can further enrich the unboxing experience and emphasize the organization’s attention to detail.

Educating end users on maintenance safeguards the appearance and structural integrity of the pieces. Light cleaning with a soft cloth, avoiding abrasive products, and displaying items out of direct sunlight can help preserve clarity over time.

Designing and producing a crystal cube laser engraving requires thoughtful preparation, collaboration, and quality control at each stage. Whether the finished product is paired with a crystal glass medal or presented as a stand-alone symbol of recognition, well-coordinated efforts yield a result that conveys significance and care. This approach allows organizations to celebrate achievements with items that hold their meaning for years to come.

English

English 中文简体

中文简体 عربى

عربى