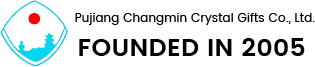

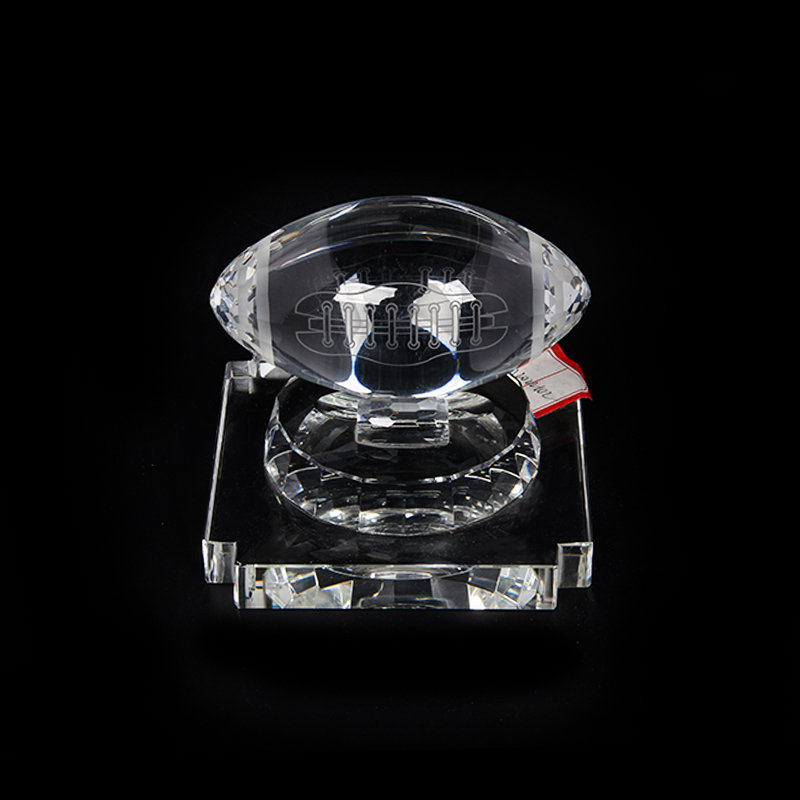

Laser engraving technology has changed the way crystal trophies are designed and produced, making them more flexible and visually appealing. Among these technological advances, double-sided laser engraving has attracted much attention for its ability to add depth and detail to crystal cube laser works and crystal glass medals. The technology can engrave on both sides of the crystal surface or inside, allowing for multi-layered designs that attract the eye and provide unique display opportunities.

Technical aspects of double-sided laser engraving

Double-sided engraving typically uses a computer-controlled laser system to etch precise patterns on both surfaces of the crystal product. For cubes or rectangular blocks, this means that the design can be applied on opposite sides, creating a sense of depth or interaction between the two sides. For thinner medals or awards, double-sided engraving can be personalized on both sides, increasing the amount of information or branding.

This method requires careful alignment and calibration to ensure that the patterns do not interfere with each other visually or structurally. Because the engraving process uses the laser to interact with the inside or surface of the crystal, there is no physical contact that could cause surface damage. The result is a smooth surface with no raised edges or risk of wear.

Design Opportunities & Visual Effects

Double-sided laser engraving opens up endless creative possibilities. For example, one side of a crystal glass award can be engraved with a sophisticated logo and text, while the other side can contain a personalized message or event details. This adds a multi-layered narrative element that elevates the significance of the award.

For crystal cube laser products, the designs on both sides can be combined to create a 3D illusion or complementary graphics that change as the viewer moves around the piece. Frosted or transparent areas can be strategically placed to highlight different parts of the design.

By using contrasting engraving depths and textures, manufacturers can create visual effects that make each award unique without the need for additional materials or coloring. This helps maintain a simple, elegant look that is appropriate for formal or corporate recognition occasions.

Production Process & Quality Control

Double-sided engraving involves multiple steps, starting with design preparation and file setup. Vector graphics must be carefully arranged, perfectly aligned with both surfaces, and precisely positioned to ensure that the final product meets the customer's expectations.

During production, the crystal is securely fixed in a fixture to prevent movement during the engraving process. Laser power and speed settings are adjusted for varying thicknesses or material properties, ensuring consistent engraving across all pieces.

Quality control includes verifying alignment, engraving clarity, and surface finish. Due to double-sided engraving, extra care is required to prevent defects such as unwanted internal cracks or surface haze that could affect transparency and overall appearance.

Practical Benefits for Custom Orders

Double-sided engraving allows for more information or decorative elements without increasing the size or weight of the award. This can be particularly helpful for clients needing to include logos, recipient names, dates, and messages within limited space.

For organizations that host annual award ceremonies or events, having a double-sided design template enables efficient batch production while still offering a high level of customization. This supports consistent branding and presentation standards across multiple orders.

Handling and Packaging Considerations

Since laser-engraved crystal products can be sensitive to scratches or chips, especially on multiple surfaces, proper packaging is essential. Protective boxes with soft linings or foam inserts help reduce damage during transit.

Clear handling instructions for clients, such as avoiding harsh cleaning agents or abrasive materials, can extend the life and clarity of both engraved surfaces. Regular dusting with soft cloths is usually sufficient to maintain the appearance.

Integrating Sustainability in Production

Laser engraving is considered a more environmentally friendly technique compared to traditional abrasive or chemical etching methods. It generates low waste and requires no inks or solvents, reducing environmental impact during production.

Some manufacturers also incorporate energy-efficient laser systems and recycling programs for crystal offcuts and packaging materials. For clients seeking to align awards with corporate sustainability goals, these factors can be part of supplier discussions.

Double-sided laser engraving on Crystal Cube Laser items and Crystal Glass Medals offers a modern, flexible option for organizations seeking to create meaningful, visually appealing awards. With precise production methods and thoughtful design, these crystal pieces can serve as lasting symbols of achievement and appreciation.

English

English 中文简体

中文简体 عربى

عربى