Customized crystal products have become an essential component of recognition events, branding, and commemorative gifts. Businesses and organizations often seek practical solutions that balance unique designs with production efficiency. Whether creating a single commemorative piece or arranging a bulk order, clear communication and careful planning can help ensure a smooth process. With the growing interest in crystal cube laser engraving and crystal glass medal production, understanding the main steps of customization can help a variety of projects achieve better results.

Planning and Design Preparation

The stage of any custom order involves clarifying design requirements and production timelines. It is recommended that customers prepare vector files or high-resolution images of logos, event details, or artwork. Providing accurate files in advance helps manufacturers convert graphics into laser-compatible formats and make adjustments.

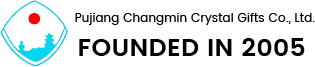

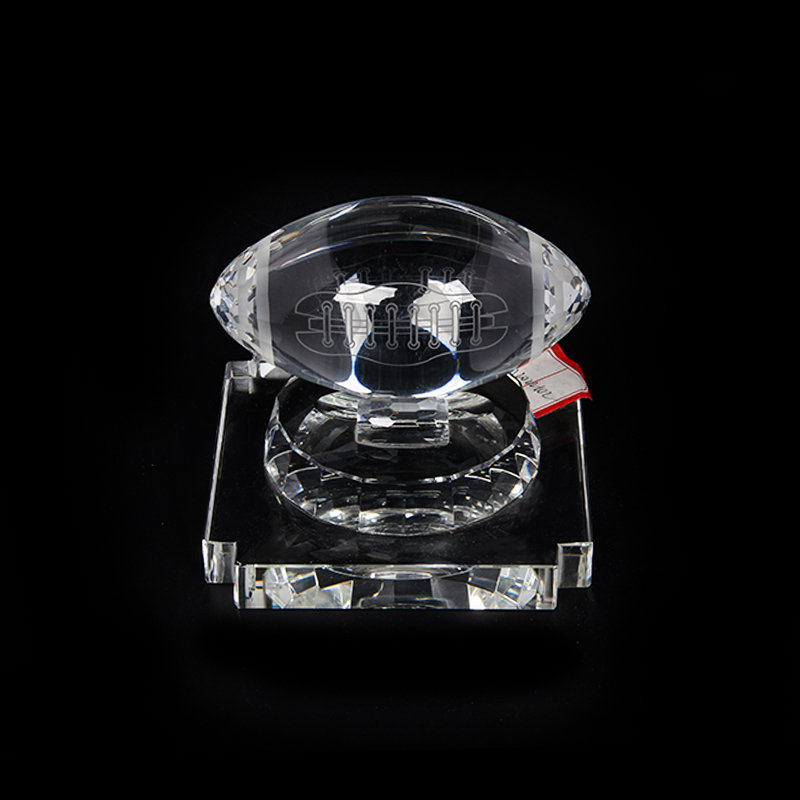

Crystal cube laser engraving uses advanced software to position the design pattern within the crystal body, creating a floating effect without interfering with the external surface. For crystal glass medals, the pattern can be applied to the front or back and combined with a frosted finish or color-filling techniques to enhance visibility.

Discussing size, shape preferences, and presentation in advance allows suppliers to provide advice on material selection and production methods. This preparation helps avoid delays or deviations between expectations and the final product.

Production Scheduling and Batch Coordination

Once the design is approved, production scheduling can begin. Custom orders are often placed in batches to maximize efficiency in the use of laser engraving equipment, polishing machines, and packaging resources. Flexible scheduling is essential for small orders where customers require delivery within a short time frame.

Manufacturers often stock a number of common crystal shapes and sizes to reduce delivery times. However, if the project requires non-standard sizes or special shapes, additional time may be required to produce and finish the blanks. When planning a batch order of crystal glass medals, customers may want to confirm whether a consistent shape or design template will be reused for future events, as this can simplify repeat orders and maintain visual continuity.

Production scheduling can also be adjusted based on seasonal demand. For example, year-end award ceremonies and the months prior to the holiday season often have larger orders. Ordering in advance can help ensure a priority delivery date and reduce the need for expedited shipping.

Material Handling and Quality Control

The durability and clarity of finished products depend on careful material handling and consistent quality checks. Optical-grade crystal is selected for its transparency and uniformity, which contribute to the final appearance. During cutting and shaping, protective measures are taken to avoid chipping and surface marks.

The laser engraving process is monitored to ensure accurate positioning and proportions of the pattern. Because the Crystal Cube laser technology creates the image internally, there is little risk of scratching the engraved area during the final polishing process.

Quality control typically includes checking engraving depth, alignment, edge smoothness, and any color applications. For larger batches, spot checks are conducted at multiple stages to confirm that each unit meets agreed specifications.

Packaging and Presentation Options

Presentation plays a significant role in the perceived value of awards and commemorative items. Crystal Glass Medals and laser-engraved cubes are often paired with protective packaging that prevents scratches and supports a professional appearance.

Common options include velvet-lined boxes, rigid cartons, or display cases. For corporate orders, many clients request custom inserts or printed sleeves that feature brand colors or event information. While packaging options can be standardized, providing clear instructions about labeling or inserts can help create a cohesive look.

Export shipments often require additional reinforcement to protect the items in transit. Clients with international delivery destinations should confirm packing requirements and allow time for customs processing.

Streamlining Reorders and Series Production

Many organizations plan for repeat orders or series production across multiple events. For example, annual awards programs or product launches may use a consistent design framework that only changes recipient details or dates.

To simplify reordering, suppliers can maintain digital templates and reference samples. This approach reduces setup time and ensures alignment with previous batches. Keeping a record of approved materials, dimensions, and finishing techniques also helps maintain visual consistency.

Clients who anticipate multiple orders can also consider pre-purchasing raw material stock or reserving production slots during peak seasons. This planning can help avoid unexpected production timeline delays and support predictable budgeting.

Balancing Efficiency and Customization

While every project has its own unique considerations, efficient scheduling combined with clear design guidance is one of the more reliable ways to achieve satisfactory results. For the production of crystal cube lasers and crystal glass medals, working with an experienced supplier who understands the technical requirements and logistics can help reduce problems and ensure consistent quality.

By integrating thoughtful design preparation, proactive scheduling, and attention to handling, businesses can create crystal awards and promotional pieces that reflect their brand and recognize achievements in a lasting way.

English

English 中文简体

中文简体 عربى

عربى