Behind every refined award presentation, there is a detailed production process that transforms raw materials into a meaningful symbol of recognition. A Crystal Glass Trophy is not created overnight, nor is it simply shaped for visual appeal. From material selection to final inspection, each stage reflects careful planning, technical control, and an understanding of how awards are used in real ceremonies. For buyers exploring cooperation with a Crystal Pyramid Factory or sourcing crystal trophies for events, understanding how these trophies are crafted helps ensure informed decisions and appropriate expectations.

From Raw Materials to Crystal-Grade Glass

The crafting journey begins with material preparation. Crystal glass differs from ordinary glass in composition, clarity, and density. Manufacturers typically use refined silica sand combined with stabilizing minerals and clarifying agents. These materials are measured precisely before entering high-temperature furnaces, where they are melted into a uniform liquid state.

Temperature control during melting is critical. If the heat fluctuates excessively, bubbles or impurities may remain trapped inside the glass, affecting transparency. Experienced factories monitor this stage closely to maintain consistent material quality, which directly influences the visual clarity of a Crystal Glass Trophy.

Shaping the Trophy Through Molding or Cutting

Once the molten glass reaches a stable condition, it is shaped into its initial form. There are two common approaches depending on design requirements.

For standardized shapes, such as pyramid or block-style awards, molten crystal glass is poured into precision molds. These molds are designed with dimensional accuracy to ensure symmetry and balance, especially important for pyramid trophies that rely on clean geometric lines.

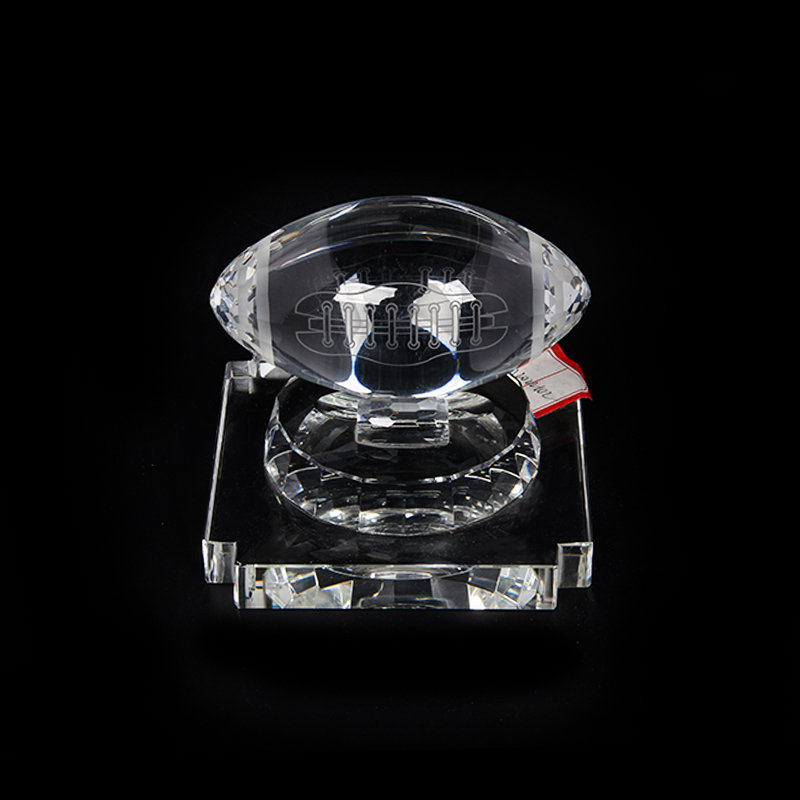

For more customized or complex forms, solid crystal blocks may be cooled and then shaped through cutting processes. Skilled technicians use diamond cutting tools to define angles, edges, and surfaces. This method allows greater flexibility in design but requires more time and technical involvement.

Controlled Cooling and Stress Reduction

After shaping, the crystal glass must cool gradually. Rapid cooling can cause internal stress, causing cracks or structural weakness over time. To prevent this, trophies are placed into annealing ovens where temperature decreases in controlled stages.

This annealing process stabilizes the internal structure of the crystal, making the final trophy suitable for long-term display and handling. Buyers sourcing from a Crystal Pyramid Factory often evaluate this step closely, as improper cooling can affect durability even if the trophy looks acceptable.

Surface Polishing and Optical Refinement

Polishing is where the trophy begins to take on its recognizable brilliance. Raw crystal surfaces appear dull and uneven after shaping, so polishing is required to improve light reflection and smoothness.

Factories may use a combination of mechanical polishing wheels and fine abrasives to refine surfaces. For areas requiring higher transparency, such as flat faces intended for engraving, additional polishing passes are applied. The goal is to achieve consistent clarity without altering the intended dimensions or edges of the design.

Engraving and Personalization Techniques

Personalization gives a Crystal Glass Trophy its emotional and commemorative value. Engraving methods vary depending on the design and information required.

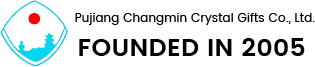

Laser engraving is commonly used for text, logos, and detailed graphics. It allows precise marking without direct surface contact, reducing the risk of chipping. Some trophies also feature internal 3D laser engraving, where images or text appear suspended inside the crystal block.

Traditional sandblasting remains an option for deeper surface engraving, particularly for larger fonts or bold logos. Each method has practical applications, and experienced factories advise buyers based on artwork complexity and display requirements.

Assembly and Final Finishing

Certain trophy designs include multiple components, such as a crystal body combined with a metal base or accent. These elements are assembled after engraving, ensuring alignment and stability.

Before packaging, each Crystal Glass Trophy undergoes visual inspection. This includes checking for surface marks, engraving accuracy, edge uniformity, and overall balance. Factories also verify that the trophy sits securely on flat surfaces, an often-overlooked detail that affects presentation quality during award ceremonies.

Practical Considerations for Buyers

Understanding the crafting process helps buyers evaluate product specifications more effectively. When discussing projects with a Crystal Pyramid Factory, it is useful to confirm details such as material composition, engraving methods, tolerance levels, and packaging standards. These factors influence not only appearance but also shipping safety and long-term storage.

A well-crafted Crystal Glass Trophy reflects attention to process rather than decorative excess. Its value lies in clarity, proportion, and suitability for the occasion it represents. By understanding how these trophies are made, purchasers can select designs that align with both event purpose and recipient expectations, ensuring the award remains meaningful long after the presentation moment has passed.

English

English 中文简体

中文简体 عربى

عربى