Award design often starts with surface details such as engraving and finish, but shape plays an equally important role in how a Crystal Glass Trophy is perceived and used. Shape influences balance, visibility, engraving layout, and how the award fits into a specific event context. For buyers working with a Crystal Pyramid Factory, choosing custom shapes is not only a design preference but also a practical decision that can address presentation needs, branding alignment, and display conditions more effectively than standard forms.

Shape as a Functional Design Element

The shape of a trophy affects more than appearance. Weight distribution, center of gravity, and handling comfort are all influenced by form. Custom shapes allow these functional aspects to be adjusted based on how the trophy will be presented, carried, or displayed.

For example, a wider base may be selected for events where trophies are placed on open stages, while taller, narrower profiles may suit formal display cabinets. Custom shaping allows the Crystal Glass Trophy to align with these real-world usage scenarios rather than adapting the event to a fixed design.

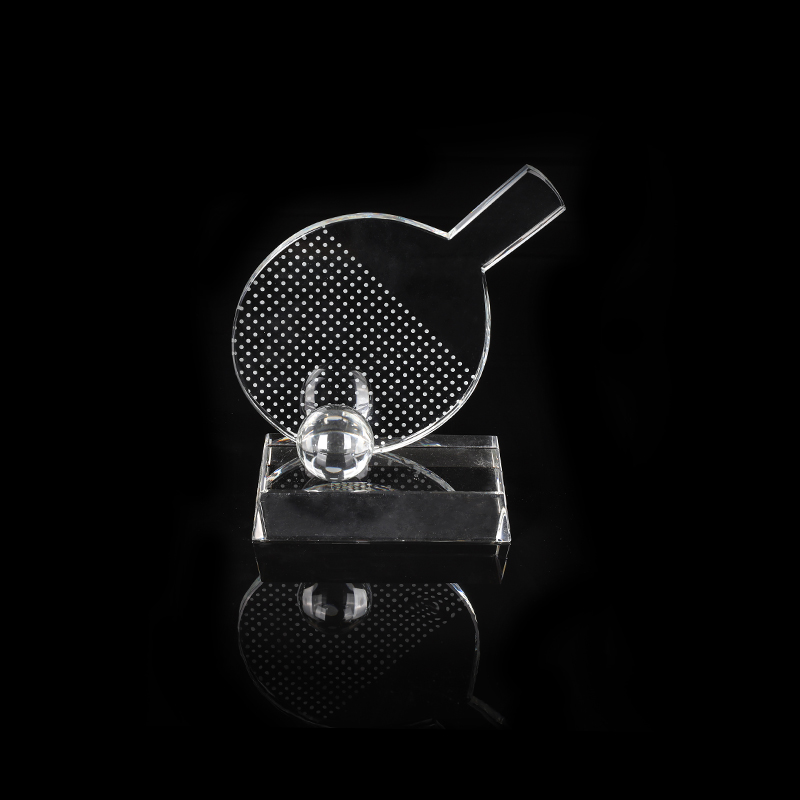

Adapting Shape to Event Identity

Different events communicate different values. Corporate recognition programs, academic ceremonies, and cultural awards often require distinct visual languages. Custom shapes help translate these identities into physical form without relying on decorative elements.

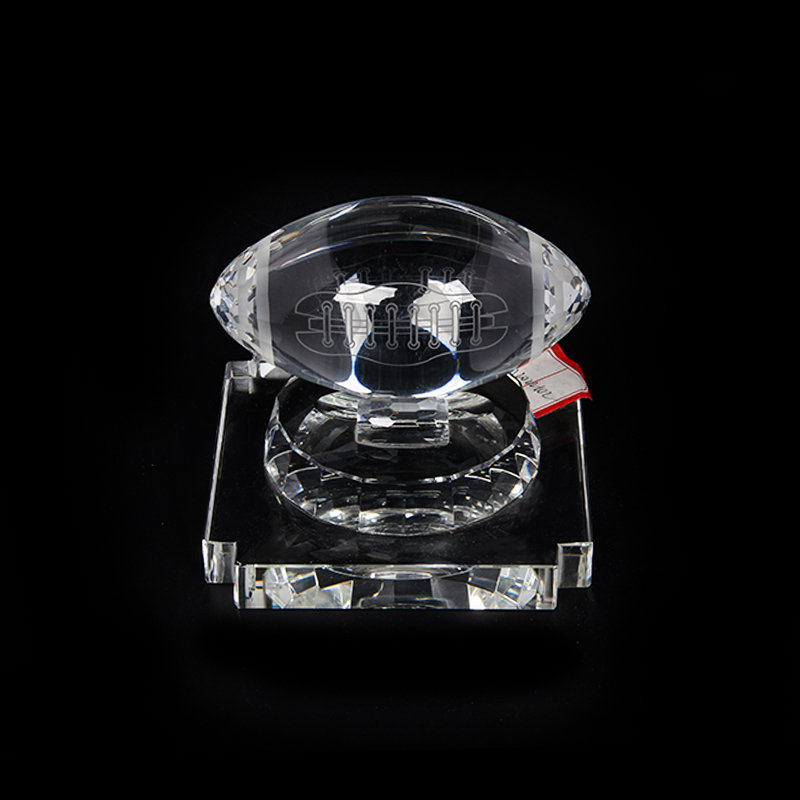

A geometric pyramid shape may suggest structure and progression, while curved or asymmetric forms can reflect creativity or innovation. Working with a Crystal Pyramid Factory on shape customization allows buyers to integrate these visual cues directly into the trophy structure, supporting thematic consistency across the event.

Improving Engraving Layout and Readability

Engraving space is directly affected by shape. Standard trophy designs may limit layout options, especially when multiple text lines, logos, or symbols are required. Custom shapes provide greater flexibility in defining flat surfaces, angles, or focal points for engraving.

By adjusting face size or orientation, custom designs can improve text spacing and alignment. This helps maintain legibility under varied lighting conditions. For Crystal Glass Trophy projects involving complex artwork or multilingual text, shape customization supports clearer visual hierarchy without increasing engraving depth or contrast.

Managing Light Reflection and Visual Balance

Crystal interacts strongly with light, and shape determines how light enters, refracts, and exits the material. Standard shapes may create uneven reflections or glare depending on lighting placement.

Custom shaping allows designers to control angles and surface transitions more deliberately. Pyramid forms with adjusted edge bevels or face proportions can distribute light more evenly across surfaces. This approach supports consistent appearance during photography, stage presentation, and long-term display.

Aligning Shape With Brand or Symbolic Elements

Many buyers seek trophies that reflect logos, architectural forms, or symbolic motifs associated with their organization or event. Custom shapes allow these elements to be referenced subtly through geometry rather than surface decoration.

A Crystal Pyramid Factory can translate abstract concepts into proportion and structure, such as upward movement, stability, or connection. This integration allows the Crystal Glass Trophy to carry meaning through form while keeping the surface design restrained and professional.

Addressing Size and Storage Requirements

Standard trophies may not always suit logistical constraints. Storage space, packaging dimensions, and transport methods can all influence shape selection.

Custom shapes can be designed to fit specific packaging systems or display environments. For large award programs, this flexibility helps manage storage and shipping more efficiently. Adjusting height, width, or thickness without altering material quality allows buyers to meet practical requirements without sacrificing visual consistency.

Supporting Consistency Across Award Series

Many recognition programs involve multiple award levels or annual editions. Custom shapes make it possible to create a consistent design language while introducing subtle variations.

For example, a base shape may remain constant while height or angle changes indicate different award tiers. This approach supports continuity while allowing differentiation. When coordinated with a Crystal Pyramid Factory, these adjustments can be planned across production cycles to maintain alignment over time.

Material Behavior and Shape Compatibility

Crystal glass behaves differently depending on thickness and geometry. Custom shapes allow material behavior to be considered during design rather than corrected after production.

Thicker sections may require adjusted cooling processes, while sharp angles may benefit from softened transitions. Designing shape with material behavior in mind supports structural stability and consistent clarity. This approach reduces the need for later modifications and supports predictable outcomes.

Prototyping and Sample Evaluation

Choosing a custom shape often involves prototyping. Physical samples allow buyers to evaluate balance, appearance, and engraving placement under real conditions.

This stage provides practical feedback that drawings or renderings cannot fully capture. Reviewing samples helps confirm that the Crystal Glass Trophy meets both aesthetic and functional expectations before full production begins.

Cost Planning and Production Efficiency

Custom shapes are sometimes assumed to increase complexity, but thoughtful design can support efficient production. When shape customization aligns with existing tooling capabilities or modular design principles, production remains manageable.

Clear communication with a Crystal Pyramid Factory during early planning helps align shape choices with feasible processes. This collaboration supports predictable timelines and consistent output without introducing unnecessary adjustments later.

Choosing custom shapes when ordering a Crystal Glass Trophy allows buyers to address functional needs, visual identity, and long-term use more directly than standard designs. Shape becomes a practical tool rather than a decorative feature, supporting clarity, balance, and relevance. When shape decisions are made with material behavior and presentation context in mind, the final trophy integrates smoothly into its intended environment and maintains visual coherence throughout its display life.

English

English 中文简体

中文简体 عربى

عربى