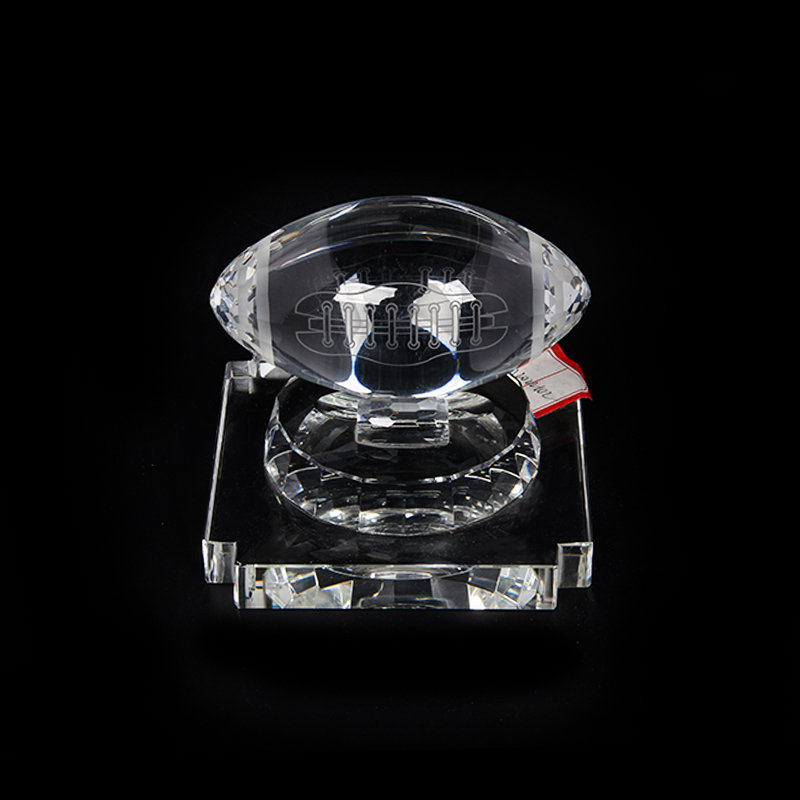

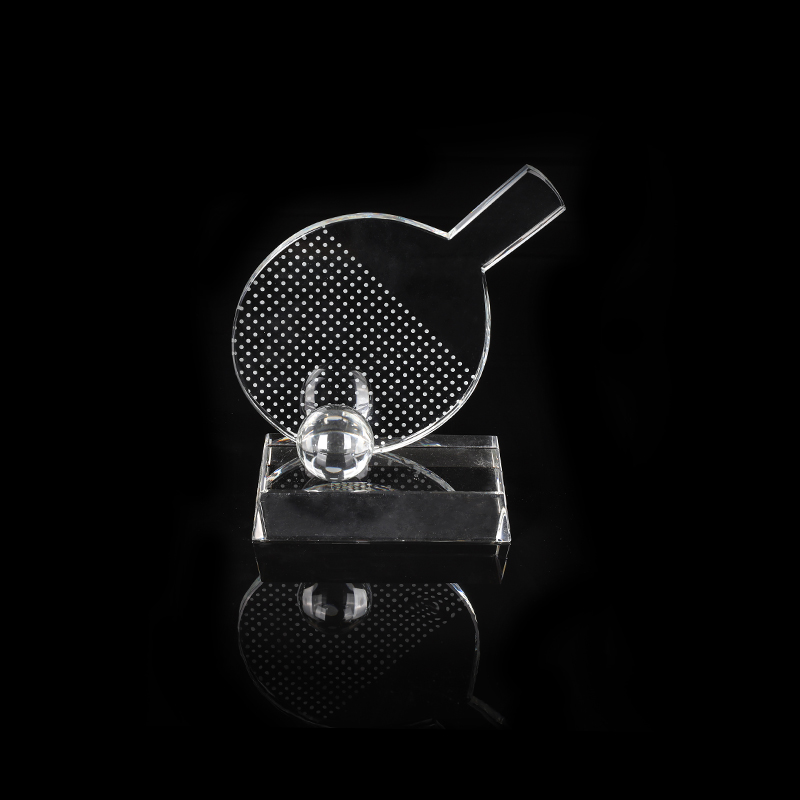

When a Crystal Glass Trophy is displayed as part of an award ceremony, its visual uniformity often goes unnoticed—until inconsistencies appear. Differences in transparency, tone, or surface response can distract from the meaning of recognition. For buyers working with a Crystal Pyramid Factory, material consistency is therefore a practical concern rather than a technical abstraction. Consistency determines whether trophies ordered months apart look aligned, whether engraving appears uniform, and whether finished products meet predictable expectations across different projects.

Raw Material Selection as the Starting Point

Material consistency begins with how raw materials are sourced and qualified. Crystal glass production relies on carefully selected silica sand, stabilizing minerals, and refining additives. Variations in purity, moisture content, or particle size can affect melting behavior and final appearance.

Factories typically work with fixed material specifications and approved suppliers to reduce variation. Incoming materials are checked for visible contamination and stored under controlled conditions. This step does not guarantee uniformity on its own, but it reduces unpredictable differences before production starts.

Batch Formulation and Measurement Control

Once materials are approved, batch formulation becomes critical. Each production batch follows a defined recipe that specifies material ratios and processing conditions. Even small deviations in measurement can influence clarity, density, or color tone.

Factories often rely on calibrated weighing systems and documented mixing procedures. These controls help ensure that each batch of crystal glass responds similarly during melting and forming. For Crystal Glass Trophy projects requiring repeat orders, consistent batch formulation supports visual alignment across multiple production cycles.

Melting Process Stability and Monitoring

Material consistency depends heavily on how raw ingredients are transformed into molten glass. Temperature stability, melting duration, and furnace conditions influence how materials interact and homogenize.

Operators monitor melting behavior to confirm that materials dissolve evenly and impurities are released during refining. If melting conditions fluctuate, differences may appear in transparency or internal structure. Maintaining stable furnace parameters supports uniform material characteristics before shaping begins.

Refining and Homogenization Practices

Refining agents are introduced during melting to assist gas release and reduce internal bubbles. The timing and quantity of these agents influence internal cleanliness.

Consistent refining practices help ensure that internal appearance remains stable across batches. In pyramid-shaped trophies, internal uniformity is particularly important, as thick sections may reveal defects more easily under lighting. Homogenization through controlled stirring or holding time allows materials to settle into a consistent structure before forming.

Controlled Cooling and Annealing Cycles

Cooling behavior reflects material consistency as much as shaping accuracy. Different material formulations respond differently to temperature changes, which may result in internal stress if not managed carefully.

Factories apply standardized cooling and annealing cycles to stabilize internal structure. By maintaining consistent cooling curves, material behavior remains predictable, reducing variation in refractive response or long-term stability. This consistency supports Crystal Glass Trophy projects intended for extended display.

Process Documentation and Traceability

Material consistency is easier to maintain when production data is recorded and reviewed. Many factories document batch numbers, material sources, melting conditions, and inspection results.

Traceability allows manufacturers to identify patterns if variation occurs. For buyers, this system supports clearer communication when reordering or adjusting specifications. A Crystal Pyramid Factory that maintains traceable records can replicate material characteristics more effectively across different orders.

Intermediate Inspection as Feedback Control

Inspection during production provides feedback on material performance. Visual checks after forming and before polishing reveal whether material consistency has been maintained.

Inspectors look for color shifts, internal haze, or surface response differences. These observations inform adjustments in later batches if needed. Rather than reacting only at final inspection, intermediate checks support gradual correction without disrupting overall production schedules.

Polishing Response as an Indicator of Consistency

How crystal responds to polishing offers insight into material uniformity. Consistent material density allows even surface refinement, while inconsistent composition may result in uneven polish or localized distortion.

Factories monitor polishing outcomes to confirm that material behavior aligns with expectations. For buyers, consistent polish response ensures that engraved areas remain clear and surfaces reflect light uniformly across multiple trophies.

Managing Variation Across Different Trophy Designs

Material consistency becomes more complex when producing different trophy sizes or shapes. Thicker crystal sections may behave differently from thinner ones, even with identical material composition.

Factories address this by adjusting process parameters while keeping material formulation stable. This approach allows varied designs to share similar visual qualities without altering core material characteristics. For Crystal Glass Trophy collections that include multiple formats, this practice helps maintain overall cohesion.

Communication Between Buyers and Manufacturers

Buyers play a role in supporting material consistency by providing clear requirements and reference samples. Sharing expectations for clarity, tone, or engraving visibility helps factories align material control with project goals.

Discussing reorders or future expansions early allows manufacturers to plan material usage and batch scheduling accordingly. This coordination reduces the risk of unintended variation between production runs.

Material consistency in a Crystal Pyramid Factory is achieved through a combination of controlled sourcing, standardized processes, and continuous observation rather than a single technical adjustment. When these elements work together, a Crystal Glass Trophy maintains predictable appearance and performance across batches and timeframes. This stability supports confident purchasing decisions and ensures that recognition remains visually aligned with the significance it represents.

English

English 中文简体

中文简体 عربى

عربى