Engraving is where a Crystal Glass Trophy moves beyond form and becomes a personalized symbol of recognition. Names, dates, logos, and messages transform a clear crystal shape into a meaningful award tied to a specific moment or achievement. For buyers planning a project with a Crystal Pyramid Factory, understanding engraving options is essential, as each method interacts differently with crystal material, surface finishes, and viewing conditions. Selecting the right approach helps ensure clarity, durability, and practical readability rather than decorative excess.

Surface Laser Engraving and Its Practical Use

Surface laser engraving is widely used for crystal trophies due to its precision and consistency. This method applies focused laser energy to the outer surface of the crystal, creating a frosted appearance where material structure is altered at a shallow depth.

This approach works well for text, logos, and simple graphics that need to be read easily at close range. On a Crystal Glass Trophy with polished faces, surface laser engraving provides controlled contrast without penetrating deeply into the material. Buyers often choose this method for awards that will be handled frequently, as surface markings remain stable when proper engraving depth is selected.

Internal Laser Engraving for Enclosed Designs

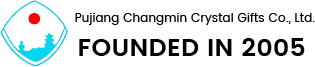

Internal laser engraving places text or images inside the crystal block rather than on the surface. A laser beam is focused at specific internal points, creating tiny fractures that form visible shapes suspended within the crystal.

This option is often used for logos, emblems, or three-dimensional imagery that benefits from depth. For pyramid-shaped trophies, internal engraving can align well with geometric forms, creating a centered visual effect when viewed from multiple angles. Buyers should note that internal engraving relies heavily on base material clarity; internal haze or bubbles may reduce visibility.

Sandblasted Engraving for Deeper Texture

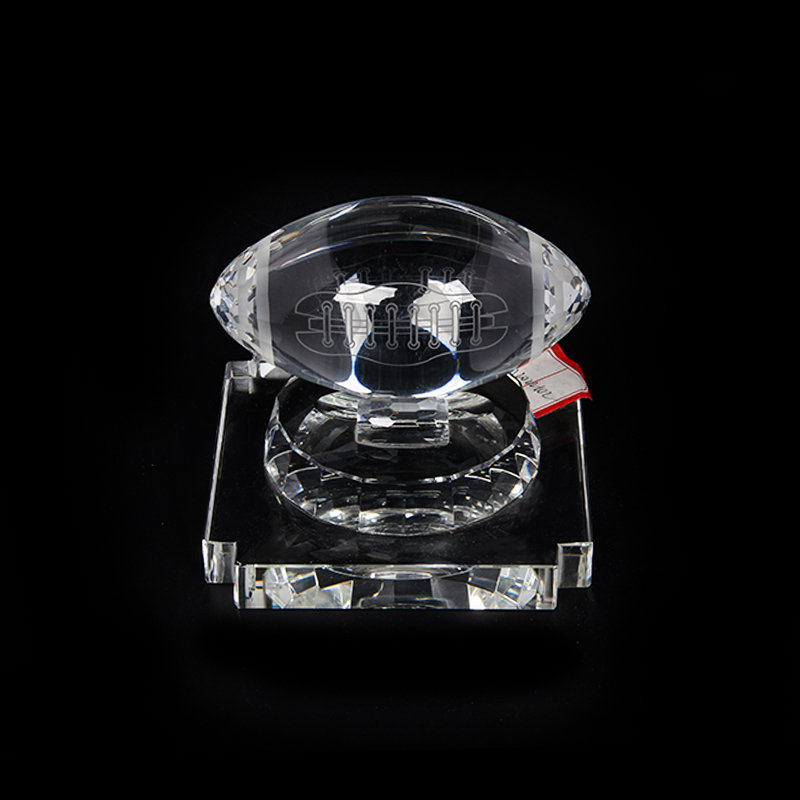

Sandblasted engraving uses abrasive particles directed at masked areas of the crystal surface. This method produces deeper, more tactile markings compared to laser engraving.

Sandblasting is suitable for larger text or bold graphic elements where depth and texture are desired. On a Crystal Glass Trophy intended for display rather than frequent handling, sandblasted areas can maintain consistent appearance over time. This method is also useful when combining engraving with matte or satin finishes, as it integrates naturally with textured surfaces.

Etching Depth and Readability Considerations

Engraving depth affects both visibility and long-term appearance. Shallow engraving may appear subtle under low lighting, while deeper engraving provides stronger contrast but may alter surface smoothness.

Factories typically adjust engraving depth based on crystal thickness and surface finish. For pyramid trophies with flat faces, depth consistency helps maintain uniform appearance across multiple sides. Buyers working with a Crystal Pyramid Factory often review sample engravings under actual lighting conditions to confirm legibility.

Font Selection and Graphic Complexity

Not all fonts perform equally well on crystal. Fine lines and complex scripts may lose definition depending on engraving method and surface finish. Simpler fonts with balanced stroke widths tend to remain clearer, especially for smaller text.

Graphic complexity also influences engraving choice. Detailed logos may benefit from internal laser engraving, while bold symbols work well with surface methods. Early artwork review helps prevent adjustments later in production, saving time and reducing variation across trophies.

Engraving Placement and Visual Balance

Placement affects how engraved elements interact with the trophy’s shape. Centered engraving suits symmetrical designs such as pyramids, while lower placement may work better for trophies with wide bases.

Spacing between engraved elements is also important. Overcrowded layouts can reduce clarity, particularly on smaller Crystal Glass Trophy formats. Factories often provide layout proofs to help buyers visualize proportions before engraving begins.

Compatibility With Surface Finishing Methods

Engraving should be planned alongside surface finishing. Polished surfaces enhance contrast for internal engraving, while matte finishes support surface text visibility by reducing glare.

If multiple finishing techniques are used on one trophy, engraving areas are usually defined in advance to avoid overlap or uneven results. Coordination between finishing and engraving teams supports consistent outcomes across production batches.

Durability and Maintenance Factors

Different engraving methods respond differently to handling and cleaning. Surface engravings remain stable under standard cleaning practices but may show fingerprints more readily on polished areas. Internal engravings are protected from surface contact but rely on overall crystal clarity for visibility.

Buyers planning long-term display should consider how the trophy will be maintained. Clear guidance on cleaning methods helps preserve engraving appearance without introducing surface wear.

Sample Approval and Quality Verification

Before full production, sample engraving approval helps confirm expectations. Reviewing physical samples allows buyers to assess contrast, alignment, and overall readability under realistic conditions.

This step is particularly useful when coordinating with a Crystal Pyramid Factory on large orders, as it ensures consistency across multiple trophies. Adjustments made at the sample stage are easier to implement than changes after full production.

Engraving transforms a Crystal Glass Trophy into a personalized award through careful alignment of method, material, and design intent. Rather than focusing on decorative impact, effective engraving prioritizes clarity, proportion, and suitability for the trophy’s intended use. When engraving options are selected thoughtfully, the final award communicates recognition clearly and remains visually consistent throughout its display life.

English

English 中文简体

中文简体 عربى

عربى