When a Crystal Glass Trophy reaches its final production stage, finishing methods play a decisive role in how the award appears, feels, and performs during presentation and long-term display. For buyers working with a Crystal Pyramid Factory, understanding finishing options is not simply about aesthetics. Each method affects surface clarity, edge definition, engraving visibility, and maintenance requirements. Knowing how these techniques function in practice helps purchasers select finishes that align with event settings, handling conditions, and design expectations.

Polished Surfaces and Light Interaction

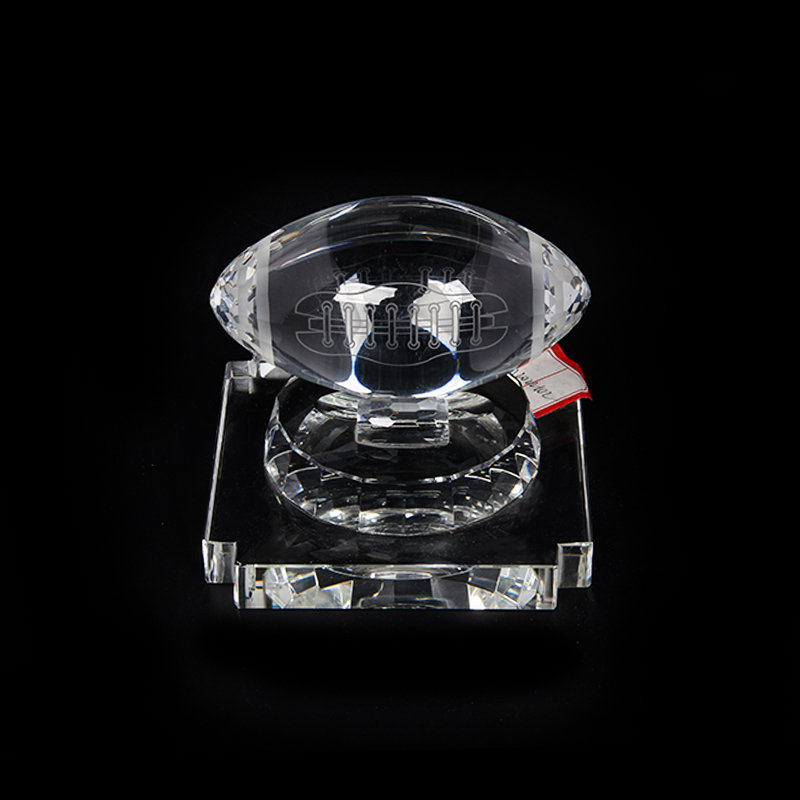

Mechanical polishing is one of the common finishing methods used for crystal pyramid trophies. After shaping and cooling, abrasive wheels and polishing compounds are applied to smooth surfaces and reduce fine marks left by cutting or molding.

Polished finishes support even light reflection, making the trophy appear clearer under stage lighting or display cases. For pyramid forms, where flat planes meet at sharp angles, consistent polishing helps maintain uniform brightness across all faces. Buyers should note that polishing quality depends on both technique and material composition, and deeper polishing cycles may be required for thicker crystal structures.

Matte and Satin Finishes for Controlled Reflection

Not all projects require high surface reflectivity. Matte or satin finishes are sometimes selected to reduce glare, especially in environments with strong overhead lighting or photography use.

These finishes are achieved through controlled surface abrasion, creating a fine-textured appearance. While the surface becomes less reflective, internal clarity remains visible. For Crystal Glass Trophy projects involving engraved logos or text, a satin background can provide contrast that improves readability without altering the trophy’s structural design.

Edge Beveling and Shape Definition

Edge treatment is particularly relevant for pyramid-style trophies, as edges define the geometric character of the piece. Beveling involves trimming and polishing the edges at precise angles to soften sharp lines while preserving symmetry.

This finishing method reduces the risk of chipping during handling and shipping. It also influences how light refracts through the trophy, as beveled edges can create subtle visual depth without relying on decorative elements. Buyers evaluating options from a Crystal Pyramid Factory often request sample bevel profiles to assess how they complement the overall form.

Surface Coating and Protective Treatments

Some crystal trophies receive transparent surface coatings designed to reduce surface marking from fingerprints or light abrasion. These coatings are applied after polishing and do not alter the underlying crystal structure.

While coatings do not prevent all wear, they can support easier maintenance during events where trophies are handled repeatedly. For long-term display, coated surfaces may reduce the visibility of minor surface contact marks, though buyers should confirm compatibility with cleaning practices.

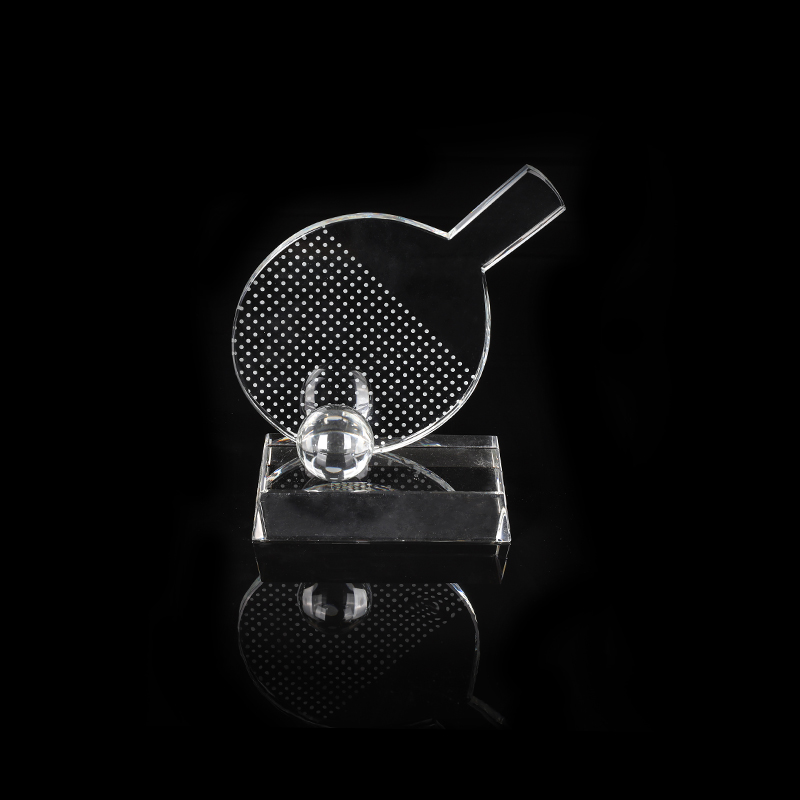

Sandblasting for Selective Texture Control

Sandblasting is often used as a localized finishing method rather than a full-surface treatment. By directing fine abrasive particles onto specific areas, manufacturers can create frosted patterns, text backgrounds, or design accents.

This approach is particularly useful when engraving needs visual separation from the surrounding surface. On a Crystal Glass Trophy, sandblasted zones can frame logos or award titles without adding color or external materials. Precision masking ensures that only intended areas are affected, preserving overall clarity.

Finishing Choices and Engraving Compatibility

Finishing methods should be selected with engraving techniques in mind. Laser engraving interacts differently with polished and matte surfaces, as contrast levels vary depending on surface reflectivity.

Polished surfaces tend to highlight internal laser engraving, while matte finishes support surface-etched designs. Buyers planning complex personalization should discuss finishing and engraving together, ensuring that both processes complement each other rather than compete visually.

Practical Considerations for Handling and Display

Finishing also affects how a trophy performs outside the factory. Highly polished surfaces may show fingerprints more easily, while matte finishes can conceal minor contact marks. Beveled edges contribute to safer handling during award ceremonies, particularly when trophies are passed between presenters and recipients.

Display environments matter as well. A Crystal Pyramid Factory project intended for permanent office display may prioritize different finishes than trophies used for large-scale events or traveling exhibitions.

Evaluating Finishing Methods During Project Planning

Selecting finishing methods early in the design phase helps align expectations across production stages. Requesting physical samples or surface references allows buyers to evaluate how finishes appear under real lighting conditions.

A Crystal Glass Trophy does not rely on complex decoration to communicate its purpose. Its visual impact comes from balanced finishing choices that support clarity, form, and usability. When finishing methods are matched thoughtfully to project requirements, the final trophy integrates smoothly into award presentations and long-term displays, maintaining a consistent appearance without unnecessary embellishment.

English

English 中文简体

中文简体 عربى

عربى